+86 512 5879 0108

+86 512 5879 0108

As an efficient and convenient hot air tool, heat gun has been widely used in many industries. He is an essential tool for some professional plastic welders as well as DIY enthusiasts in the field of plastic welding. With the development of technology, more and more different kinds of heat guns appear on the market,

During the floor installation process, heat guns can be used to quickly heat the floor material, making it softer, easier to bend and fit. This is useful for installing curved or irregularly shaped floors. At the same time, the heat gun can also speed up the drying process of the floor glue and improve the installation efficiency.

A heat gun can be used as an effective repair tool when the floor is warped, cracked or deformed. By heating the floor material, it can be restored to its original shape and size, thus repairing damaged parts. In addition, the heat gun can be used to remove stains and stubborn residues from the floor.

During the floor renovation process, a heat gun can be used to strip away old floor coatings or paint, providing a clean surface for repainting or coating. Compared with traditional mechanical stripping methods, the use of heat guns can reduce the damage to the floor material and improve the quality of the renovation.

During the construction of the waterproof layer of the roof, the heat gun can be used to heat and melt the waterproof coil to make it better bonded to the base. This can not only improve the tightness and durability of the waterproof layer, but also reduce defects such as bubbles and gaps in the construction process.

A heat gun can be used as a quick and effective repair tool when a roof is leaking, cracking, or aging. By heating and softening the roofing material, the damaged part can be repaired and its waterproof function restored. In addition, the heat gun can also be used to remove snow and debris on the roof.

During roofing renovations, heat guns can be used to strip away old waterproof layers or coatings, providing a clean base for re-laying new waterproof materials. Compared with the traditional mechanical stripping method, the use of heat gun can reduce the damage to the roof structure and improve the efficiency and quality of renovation.

In the production and processing of tarpaulin, multiple tarpaulins need to be welded together to form a larger coverage area. By blowing out high temperature air, the hot air gun makes the tarpaulin material quickly melt and bond together, thus achieving a strong welding effect.

When the tarpaulin is broken or leaky, the damaged part can be heated and melted using a heat gun, and then filled and repaired with the same or similar material. This method can quickly and effectively restore the waterproof performance and service life of the tarpaulin.

During the processing of automotive interiors, heat guns can be used to heat and shape various plastic and leather materials. For example, parts such as seats, door panels and the center console are manufactured using a heat gun to heat and shape the material.

When installing automotive glass, a heat gun can be used to heat the edges of the glass, making it softer and easier to install into the body frame. At the same time, the heat gun can also be used to remove residues such as glue and stains from the glass.

When the car's paint is scratched, dented or chipped, the damaged part can be heated and treated with a heat gun for better filling, sanding and repainting operations. This restores the flatness and gloss of the car's surface.

During the construction of the waterproof layer of the building, the waterproof coil can be heated and melted using a heat gun to make it better adhere to the base. This can improve the tightness and durability of the waterproof layer, preventing problems such as leakage and moisture in the building.

During the processing of building materials, heat guns can be used to cut, bend and shape various materials such as plastics, metals and wood. For example, in the manufacture of components such as doors and Windows, pipes, and decorative pieces, the material needs to be heated and treated with a heat gun.

During the architectural decoration process, the heat gun can be used to remove residues such as old coatings, paints and stains, providing a clean surface for redecorating. At the same time, the heat gun can also be used to heat and soften the decorative material, making it easier to stick and secure. For example, heat guns can be used to improve construction efficiency and quality in wallpapers, installation of soft bags, and art decoration.

Local heating of a plastic sheet or bar through a heat gun can soften it and make it easy to bend into the desired shape. This method is often used to make plastic products with various curved shapes.

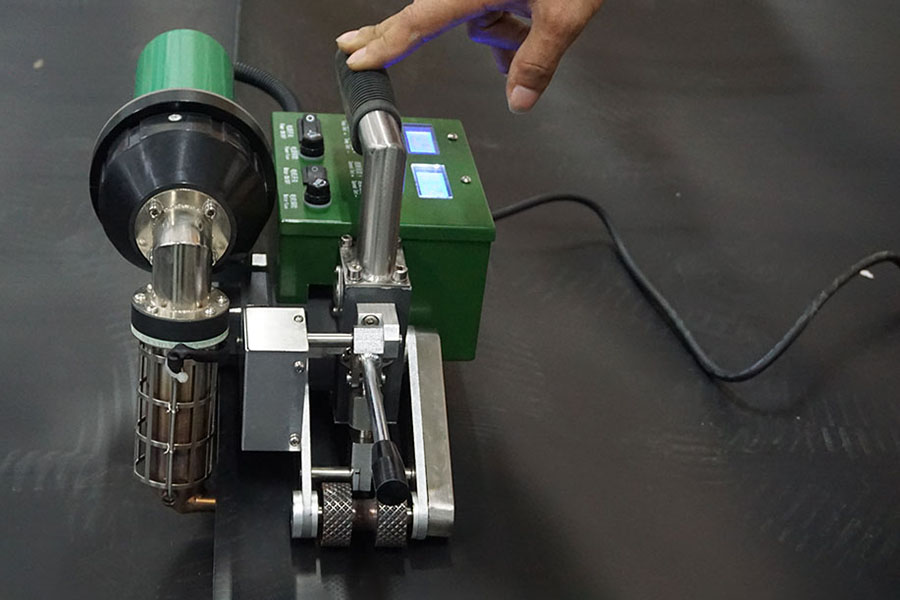

Heat guns can be used to heat and melt plastics during welding. By blowing out high temperature air flow, the contact surface of two plastic materials is melted and bonded together to form a strong welded joint. This method is widely used in the assembly and repair of various plastic products.

Heat guns can also be used for plastic shrink film applications. By heating the shrink film, it shrinks and tightly wraps the surface of the object to achieve protection, waterproof or aesthetic effect. This method is often used in the areas of packaging, protection and identification.

The waterproof layer of the swimming pool is the key to ensure that the pool water does not leak. The heat gun can be used to heat and melt the waterproof coil, making it better adhere to the base, forming a continuous, complete waterproof layer. This can improve the water resistance and service life of the pool.

When pasting tiles on the pool wall and bottom of the pool, you can use a heat gun to heat the back of the tile. This can speed up the drying and curing process of tile glue, improve the adhesion firmness and construction efficiency. At the same time, the heat gun can also be used to remove stains and residues from the surface of the tile, providing a clean base for pasting.

When laying the pond liner, you can use a heat gun to heat the liner. This makes the liner softer and easier to spread and fit on the base. At the same time, heating treatment can also enhance the adhesion between the liner and the base, improve the waterproof effect and service life.

When the pond liner is broken or leaky, a heat gun can be used to heat and melt the damaged part. It is then filled and repaired with the same or similar material to restore the integrity and water resistance of the liner. This method can solve the problem of pond leakage quickly and effectively.

To sum up, the hot air gun has a wide range of application prospects and huge market potential in the above fields. With the continuous progress and innovation of technology, we expect the heat gun to have more features and higher performance in the future. In future development, the heat gun may be further intelligent and automated to achieve more accurate temperature control and ease of operation. In addition, with the popularity of environmental protection concepts and the promotion of green building materials, heat guns may pay more attention to the improvement of environmental performance and energy saving. These innovations and developments will bring broader application prospects and market opportunities for flooring and roofing.

Previous: Common plastic welding process

ZHANGJIAGANG NEICO TOOLS CO., LTD.

Add.: NO.17-18, Building 6, International Trade City, Tangqiao Town, Zhangjiagang 215600, Jiangsu, China

Mob: +86 139 1570 3340

Tel.: +86 512 5879 0108

Fax: +86 512 5879 0108

Skype: neicotools

E-mail: sales@neicotools.com

Web: www.neicotools.com

Products

Site Map