+86 512 5879 0108

+86 512 5879 0108

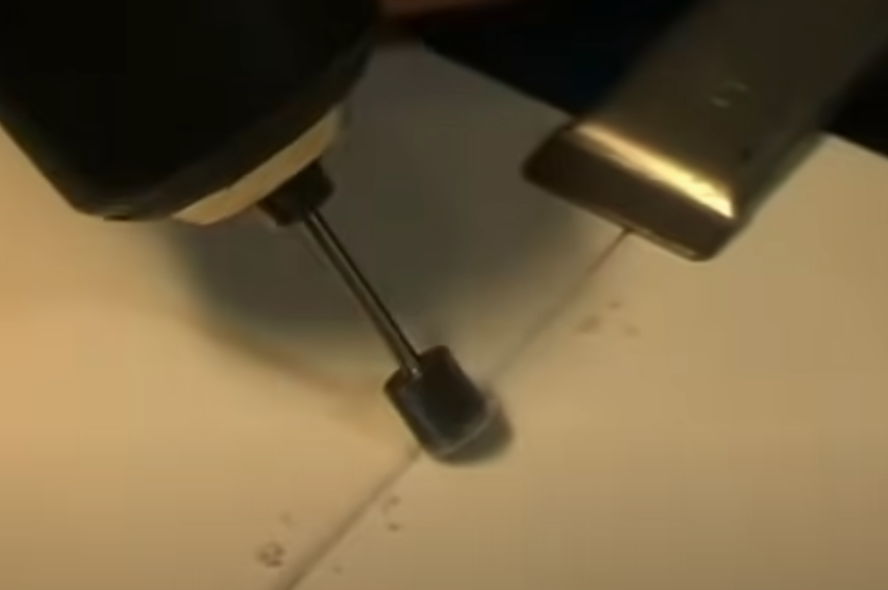

A plastic welding gun, also known as a heat gun, is a handheld tool that is used for plastic welding, particularly for the hot air welding method. It works by heating the plastic material to its melting point, allowing it to be fused together with another plastic part or component.

A plastic welding gun typically consists of a heating element, a fan or blower to direct hot air onto the plastic, and controls for adjusting the temperature and airflow. The gun may also include a nozzle or attachment to focus the heat on a specific area or joint.

Plastic welding guns are commonly used in automotive repair, construction, and fabrication industries for repairing or joining plastic parts, such as bumpers, dashboards, and other interior components. They are also used in the manufacturing of plastic products, such as PVC pipes, plastic sheets, and packaging materials.

Plastic welding guns are available in different sizes and power ratings, depending on the size and thickness of the plastic being welded. They are generally easy to use and can produce strong, durable welds when used correctly.

The process of welding plastics depends on the type of welding method being used. However, here is a general process that can be followed:

· Prepare the surfaces to be welded: The surfaces to be welded should be clean and free of any debris or contaminants. This can be done by wiping them down with a solvent.

· Choose the welding method: Select the appropriate welding method based on the type of plastic and the desired application.

· Set up the welding equipment: Set up the equipment according to the manufacturer’s instructions.

· Heat the plastic: Apply heat to the plastic surfaces to be welded. The amount of heat and the time required will depend on the type of plastic and the welding method being used.

· Apply pressure: Apply pressure to the plastic parts to be joined. The amount of pressure required will depend on the type of plastic and the welding method being used.

· Allow the plastic to cool: Once the plastic has been welded, allow it to cool down and solidify.

· Finish the welded part: Trim any excess plastic and smooth out any rough edges to create a finished product.

ZHANGJIAGANG NEICO TOOLS CO., LTD.

Add.: NO.17-18, Building 6, International Trade City, Tangqiao Town, Zhangjiagang 215600, Jiangsu, China

Mob: +86 139 1570 3340

Tel.: +86 512 5879 0108

Fax: +86 512 5879 0108

Skype: neicotools

E-mail: sales@neicotools.com

Web: www.neicotools.com

Products

Site Map