+86 512 5879 0108

+86 512 5879 0108

Teflon Seam Roller is widely used in the plastic welding process of PVC, TPO,EPDM floor and roof. For example, in applications such as civil engineering, tunneling and disposal, where the quality of the sealing system is a top priority, the Teflon Seam Roller can effectively improve the accuracy of the welding. When repairing plastic parts of cars and motorcycles, different roller sizes can also be compatible with different welding positions. Its high compatibility makes it suitable for auxiliary operations of various processes such as hot plate welding, laser welding and ultrasonic welding.

High temperature resistance and anti-viscosity: The high temperature resistance of Teflon (polytetrafluoroethylene) makes it not easy to deform during the welding process, and its very low friction coefficient can reduce the material adhesion, avoid polluting the weld, and ensure the cleanliness of the welding surface.

Chemical stability: Teflon's high resistance to acids, bases and solvents extends tool life and is particularly suitable for industrial scenarios working in complex chemical environments12.

Environmental protection and lightweight: meet the needs of modern manufacturing industry for environmentally friendly materials, while lightweight design reduces the labor intensity of operators.

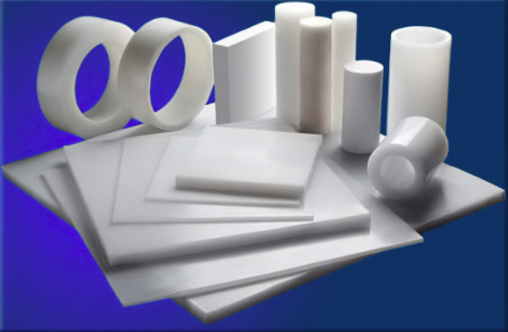

Multi-size and customized services:Roller sizes from 6mm to 90mm are available, and non-standard sizes can be customized for special workpiece requirements for a variety of scenarios, from tiny electronic components to large automotive parts.

Single Angled Offset Steel Fork:The unique Angle design improves operational flexibility in small Spaces, especially for the fine welding of complex structural workpieces

High quality ball bearings:Built-in precision ball bearings ensure smooth roller rotation, reduce friction losses, extend tool life, and improve welding uniformity.

Humanized handle design:The use of spray wood handle, both comfortable grip and anti-slip performance, long-term operation can effectively reduce operating fatigue.

The NEICO Teflon Seam Roller is sold by several manufacturers in the United States and Europe. User feedback shows that its customized services have significantly improved fit, while the durability of Teflon materials has reduced tool maintenance costs by more than 30 percent. With the growing demand for precision welding in the manufacturing industry, the market potential of such highly compatible tools will be further released.

NEICO has once again demonstrated its innovative strength in the field of industrial tools with the Teflon Seam Roller. In the future, the company plans to expand more materials and functional combinations, and continue to promote the plastic welding process to high efficiency and intelligence. For product details or customized requirements, technical support can be obtained through NEICO's official website or authorized agents.

ZHANGJIAGANG NEICO TOOLS CO., LTD.

Add.: NO.17-18, Building 6, International Trade City, Tangqiao Town, Zhangjiagang 215600, Jiangsu, China

Mob: +86 139 1570 3340

Tel.: +86 512 5879 0108

Fax: +86 512 5879 0108

Skype: neicotools

E-mail: sales@neicotools.com

Web: www.neicotools.com

Products

Site Map