+86 512 5879 0108

+86 512 5879 0108

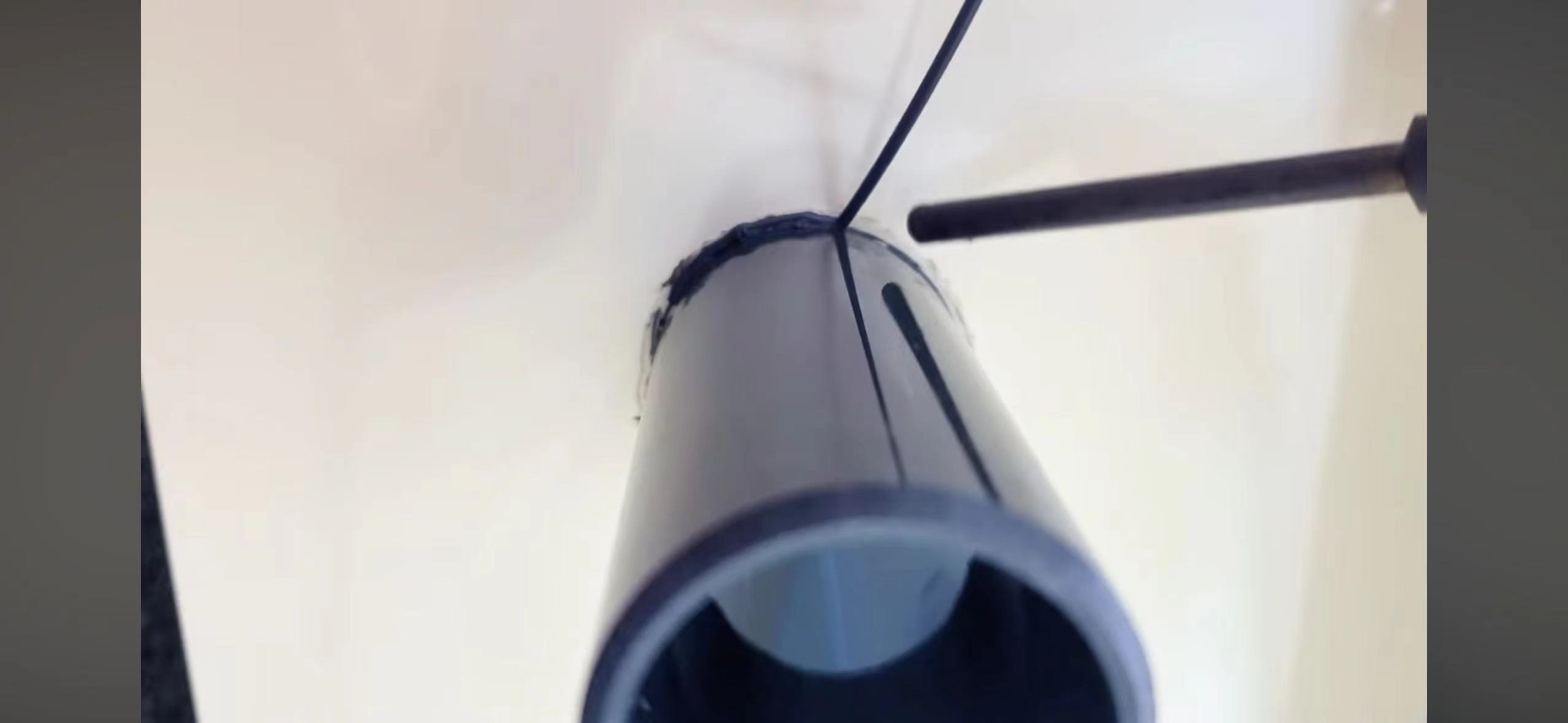

Detailed explanation of plastic pipe welding steps

Welding plastic pipes is a task that requires meticulous handling and expertise. Here are the steps for welding plastic pipes based on the Butt Fusion welding method:

1. Preliminary preparation

Select tools: According to the material and size of the pipe, select the right hot melt welding machine, heating plate, cutting tools and cleaning tools.

Check the pipeline: Ensure that the surface of the pipeline is free of damage, cracks, oil and other pollutants.Measurement and cutting: Use the pipe cutting tool to accurately cut the pipe according to the predetermined length, and ensure that the incision is smooth and burr free.

2. Cleaning and pretreatment

Cleaning work: Use special cleaning tools or sandpaper to remove oil, dust and oxide from the cut of the pipeline.

Fixed pipe: Use a fixture to fix the pipe on the hot melt welding machine to ensure that the pipe is stable and does not shift during welding.

3. heating and welding

Setting parameters: According to the pipe material and size, set the appropriate heating time and temperature.

Heating the pipe: Place the heating plate between the two pipe cuts and heat it until the pipe material reaches the melting point.

Butt fusion: When the heating time arrives, quickly remove the heating plate, butt the two pipe cuts and apply appropriate pressure until the plastic cools and solidifies.

4. check and finish

Weld inspection: After the weld is completely cooled, check whether it is smooth, no bubbles, no cracks.

Clean up the site: clean up the waste and tools generated during the welding process, keep the work area clean and tidy.

5. Precautions

Safe operation: Observe safety regulations and wear protective equipment during operation.

Material matching: Ensure that the welded pipe materials are the same, and avoid mixed welding of different materials.

Temperature and time control: strictly control the heating temperature and time to avoid excessive or insufficient melting of the pipeline.

Environmental factors: The influence of external factors such as wind and water on the weld should be avoided during the welding process.

By following the above steps and precautions, you will be able to successfully weld plastic pipes. However, please note that if you are not familiar with this process or lack the necessary tools and equipment, it is recommended to seek the help of a professional pipe welder.

Previous: Plastic Welding Kit

Next: Plastic Welding Gun

ZHANGJIAGANG NEICO TOOLS CO., LTD.

Add.: NO.17-18, Building 6, International Trade City, Tangqiao Town, Zhangjiagang 215600, Jiangsu, China

Mob: +86 139 1570 3340

Tel.: +86 512 5879 0108

Fax: +86 512 5879 0108

Skype: neicotools

E-mail: sales@neicotools.com

Web: www.neicotools.com

Products

Site Map